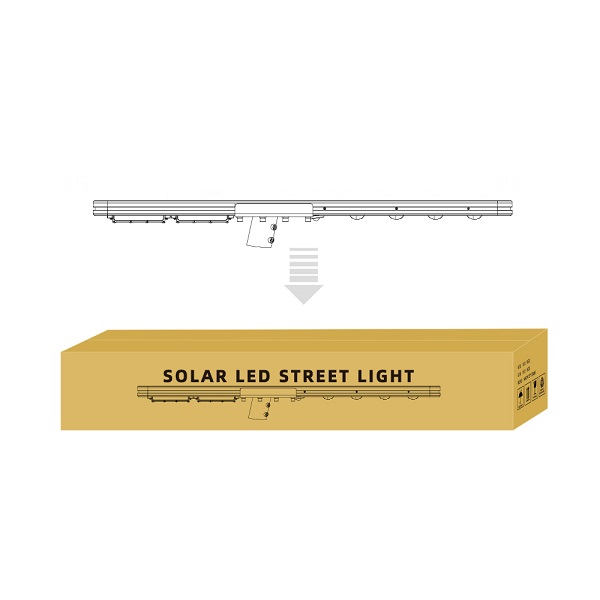

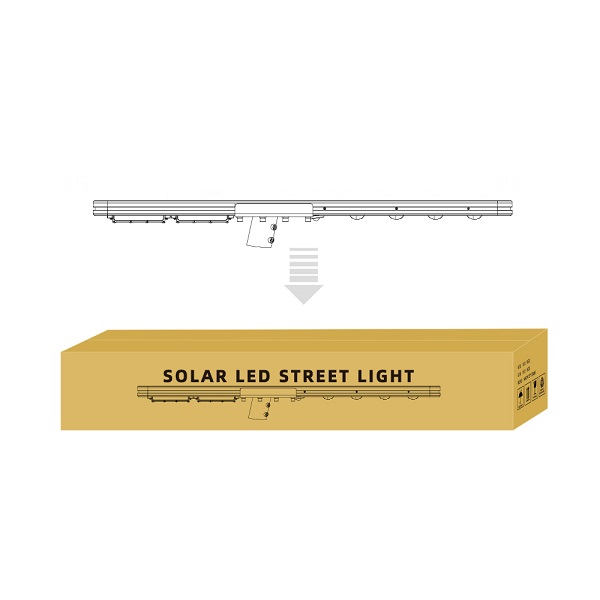

The packaging forms of solar street lights mainly include color box packaging and laminated packaging.

| Heading Level | Heading |

|---|

| H1 | How to Package Solway's Solar Street Light Products |

| H2 | Introduction to Solar Street Lights |

| H2 | Importance of Packaging |

| H3 | Protecting the Product |

| H3 | Facilitating Transportation |

| H3 | Enhancing Brand Image |

| H2 | Packaging Materials for Solar Street Lights |

| H3 | Outer Packaging Materials |

| H4 | Cardboard Boxes |

| H4 | Wooden Crates |

| H3 | Inner Packaging Materials |

| H4 | Foam Inserts |

| H4 | Bubble Wrap |

| H2 | Key Considerations in Packaging Design |

| H3 | Size and Weight |

| H3 | Environmental Factors |

| H3 | Cost-Effectiveness |

| H2 | The Packaging Process |

| H3 | Assembly and Testing |

| H3 | Labeling and Marking |

| H2 | Conclusion |

| H2 | FAQs |

How to Package Solway's Solar Street Light Products

When it comes to solar street lights, Solway stands out for its innovative designs and eco-friendly solutions. But have you ever thought about how these products are packaged? Packaging is more than just a protective layer; it plays a crucial role in the product's journey from the factory to the end user. Let’s dive into the best practices for packaging Solway's solar street light products.

The packaging forms of solar street lights are mainly divided into two types: color box packaging and laminated packaging. Color box packaging usually uses five layers of paper or thicker paper materials to provide adequate protection and support. This form of packaging is suitable for external protection of solar street lights and can effectively prevent damage during transportation. Laminated packaging is a more advanced packaging method. Through the lamination process, the working life of solar cells can be as long as 25 years.

This form of packaging is not only beautiful, but more importantly, it can significantly extend the service life of solar cells. For products like solar street lights, laminated packaging is more appropriate because it can better protect the solar panels from bending and damage, while also ensuring the performance and lifespan of the solar street lights.

In addition, the packaging of solar street lights should also take into account the safety during transportation. During loading, unloading and transportation, it is necessary to handle it with care to avoid heavy goods being pressed on top or stacked on uneven places. Correct packaging not only protects the product, but also ensures its safety during transportation. Therefore, choosing the right packaging form is crucial to protect solar street lights from damage.

Packaging Materials for Solar Street Lights

Choosing the right materials is crucial for effective packaging. Here are some common options:

Outer Packaging Materials

The outer packaging is the first line of defense. Common materials include:

Cardboard Boxes

Cardboard boxes are lightweight and easy to print on, making them a popular choice. They can be customized to fit the dimensions of the solar street lights, providing a snug fit.

Wooden Crates

For heavier or more fragile items, wooden crates offer superior protection. While they may be more expensive, they can withstand rough handling during transportation.

Inner Packaging Materials

Inner packaging is just as important for safeguarding the product. Common materials include:

Foam Inserts

Foam inserts provide cushioning and prevent movement within the box. They are lightweight and can be molded to fit the shape of the solar street light components.

Bubble Wrap

Bubble wrap is another excellent option for protecting smaller parts. It’s effective at preventing scratches and absorbing shocks during transit.

Key Considerations in Packaging Design

When designing packaging, several factors should be taken into account:

Size and Weight

The size and weight of the packaging directly impact shipping costs. Aim for a design that minimizes excess material while still providing adequate protection.

Environmental Factors

With increasing awareness of environmental issues, consider using eco-friendly packaging materials. Recyclable or biodegradable options can appeal to environmentally conscious consumers.

Cost-Effectiveness

Finally, keep an eye on costs. While it’s important to invest in quality packaging, finding a balance between protection and expense is key to maintaining profitability.

The Packaging Process

The packaging process is where all the planning comes together. Here’s how it typically unfolds:

Assembly and Testing

Before packaging, each solar street light should be assembled and tested to ensure it functions correctly. This step is crucial to avoid returns and customer dissatisfaction.

Labeling and Marking

Don’t forget to include labels and markings on the packaging. This information helps with inventory management and ensures that the right products reach the right customers.

Conclusion

In summary, packaging Solway's solar street light products is a multifaceted process that requires careful consideration of materials, design, and functionality. By prioritizing protection, transportation efficiency, and brand image, you can ensure that these innovative products reach customers safely and effectively.

FAQs

What materials are best for packaging solar street lights?

Why is packaging important for solar street lights?

How can I make my packaging more environmentally friendly?

What should I include on the packaging labels?

How can I reduce packaging costs?

English

English

Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Consult Now

Consult Now