-

-

Vertical Solar PV Poles

-

Square Shape Vertical Solar PV Poles

Round shape vertical Solar PV poles

Vertical Solar PV Poles

-

Solar Street Lights

-

Four-lane Road Width 16-20M

Two-lane Road Width 7-8M

Single Lane 3-5M

Solar Street Lights

-

Solar Garden Lighting

-

Solar garden/landscape/security lighting series

Solar Garden Lighting

-

-

-

Company Profile

Company Profile

-

Enterprise Style

Enterprise Style

-

Certification

-

Company Honor

Certified Product

Product Patent

Certification

-

-

-

SKD solution

SKD solution

-

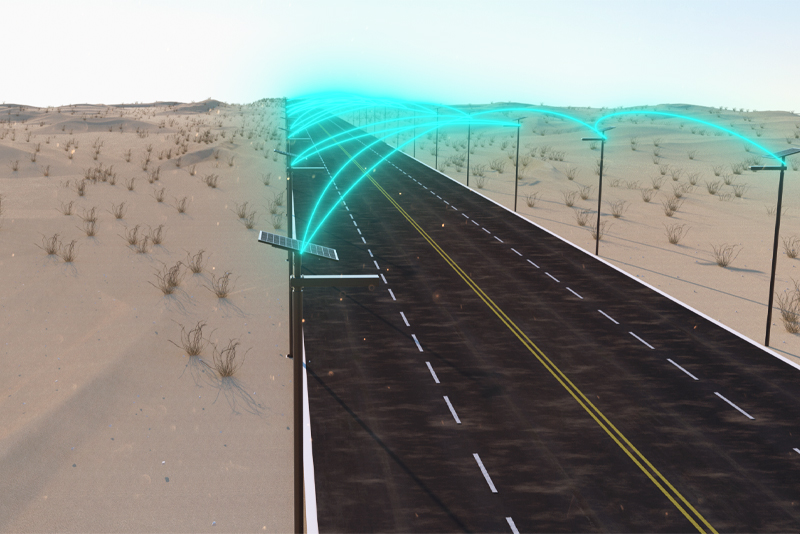

Solar IoT Management System

Solar IoT Management System

-

Solar-Grid Power Hybrid Solution

Solar-Grid Power Hybrid Solution

-

Cambodia Factory

Cambodia Factory

-

-

-

Vertical Solar PV Poles

Vertical Solar PV Poles

-

Solar Street Lights

Solar Street Lights

-

Solar Garden Lighting

Solar Garden Lighting

-

-

English

English

Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Consult Now

Consult Now