As an important lighting facility for urban development, the quality of solar LED street lights is the top priority of major projects. However, the prices of solar LED street lights in the market are varied and the quality is uneven. Many reasons are that in the Chinese market, manufacturers have weak patent awareness and lack of innovation. The industry price war has led manufacturers to continuously reduce costs in materials and processes, which has had a significant impact on the quality of solar LED street lights. It is often seen that street lights go dark after a period of use. The way to replace LED street lights is very cumbersome. This is because there are many parts inside LED street lights. In addition to the light source (chip), damage to other parts will cause the chip to not light up. It is impossible to immediately determine the cause of the damage to the LED street light on site. The LED street light needs to be removed and shipped back to the factory for various tests. This is difficult to install and even more difficult to repair for outdoor high-altitude devices such as LED street lights. For street light managers, unstable product quality makes the maintenance cost high.

Common "tricks" of LED street lamps

1. False configuration: The popularity of LED street lamps is also accompanied by a decrease in price profits. The fierce competition has also led to many businesses cutting corners and falsely marking product parameters. This is also caused by customers repeatedly comparing prices and asking for low prices, and it is also related to the practices of some manufacturers.

2. Counterfeit chips: The core of LED lamps is the chip, which directly determines the performance of the lamps! However, some unscrupulous merchants take advantage of customers' unprofessionalism and use low-priced chips for cost considerations, so that customers buy low-quality products at high prices, causing direct economic losses and serious quality risks to LED lamps.

3. Copper wire pretends to be gold wire: Many LED manufacturers try to develop copper alloy, gold-clad silver alloy wire, and silver alloy wire to replace expensive gold wire. Although these alternatives are better than gold wire in some characteristics, they are much worse in chemical stability. For example, silver wire and gold-clad silver alloy wire are susceptible to sulfur/chlorine/bromine corrosion, and copper wire is prone to oxidation and sulfide. For encapsulated silica gel similar to water-absorbing and breathable sponge, these alternatives make the bonding wire more susceptible to chemical corrosion, reduce the reliability of the light source, and LED lamp beads are more likely to break and die after a long time of use.

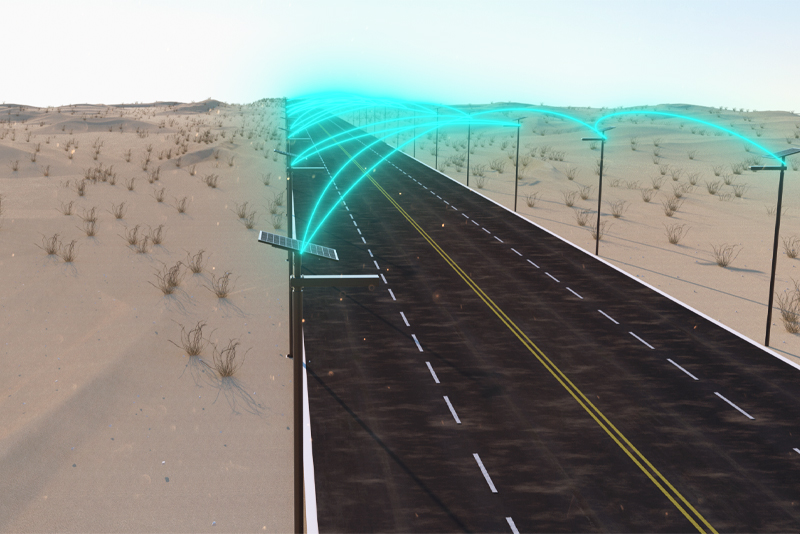

4. The design of the light distribution system of street lamps is unreasonable: In terms of optical design, if the design of the light distribution system of street lamps is unreasonable, the lighting effect is not ideal. Problems such as "bright under the lamp", "dark under the lamp", "zebra crossing", "uneven illumination", and "yellow circle" will appear in the test.

5. Poor heat dissipation design: In terms of heat dissipation design, the life of semiconductor devices will decrease exponentially for every 10 degrees increase in the PN junction temperature of the LED chip. Since LED street lamps have high brightness requirements and harsh operating environments, if the heat dissipation is not properly solved, the LED will quickly age and the stability will be reduced.

6. Power failure: In terms of the driving power supply, if the power supply fails, during the test and inspection process, there will be "whole lamp off", "partial damage", "individual LED lamp beads dead", "whole lamp flickering virtual light" phenomenon.

7. Safety failure: Safety issues are also worthy of serious attention: street lamp power supply has no leakage protection; street lamp ballast quality is inferior; circuit breaker has not been tested for sensitivity verification, and the rated tripping current is too large; the use of cable metal sheath as PE main trunk line is complex and has low reliability; IP waterproof and dustproof level is too low.

8. The presence of substances harmful to the light source in the lamp: LED light source blackening is a common problem encountered by major LED companies. Most materials in lamps need to be checked for substances that affect the life of the light source.

The emergence of the above problems has a great impact on the performance of solar LED street lights, and may even cause premature failure of LED street lights. In response to the above problems, Jinjian Testing has mature testing methods that can fully identify the advantages and disadvantages of LED street lights, put forward acceptance suggestions, and avoid subsequent losses.

English

English

Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Scan WhatsApp

Scan WhatsApp Scan Wechat

Scan Wechat Consult Now

Consult Now